Precise all-rounder for many industries: How cartridge filters work

In industry and many other applications, precise filtration is essential to ensure the purity and quality of the filtered fluids and to keep production processes running smoothly. Cartridge filters offer an outstanding solution for a wide range of requirements and guarantee maximum filtration performance. But how exactly does a cartridge filter work? What advantages does the cartridge filter function offer? And where are these systems used? In the following article, we answer these questions and give you a deeper insight into the world of cartridge filters.

What is a cartridge filter and how is it constructed?

Cartridge filters are versatile filtration systems that remove fine to very fine impurities in liquids or gases and are used in many industries. A usually cylindrical pressure vessel contains one or more filter cartridges arranged in parallel, which are made of materials such as cellulose (paper), polypropylene, polyester, cotton, acrylic fiber, glass fiber or stainless steel, depending on the application and requirements. The filter cartridges can be smooth, wound or pleated in order to fulfill a wide range of filtration tasks through surface filtration or depth filtration.

Both the filter cartridges, which are available as regenerable or disposable versions, and the filter housings can be flexibly adapted to the specific requirements and operating parameters. This modular system offers an optimum solution for individual processes.

How do cartridge filters work? How they work in detail

The cartridge filter function is based on a closed system that can reliably clean both liquids and gases. At the heart of the technology are the filter cartridges, which are arranged in parallel in multi-layer housings. The function of the filter cartridges is to remove unwanted particles from the medium. The process works as follows:

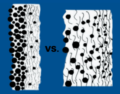

The medium to be filtered enters the dirt chamber of the filter through an inlet nozzle, flows through the upright or suspended filter cartridges from the outside to the inside and exits cleaned through the outlet nozzle. Depending on the filter type, entrained impurities whose particle size exceeds the filter fineness are retained on the surface or in the depth structure of the filter cartridge. The dirt particles retained by the filter cartridge cause an increase in the differential pressure between the dirty and clean sides of the filter. At a defined differential pressure, the filter cartridges must be replaced or, if possible, regenerated.

Cartridge filter function at a glance

In summary, the functionality of a manual cartridge filter is as follows:

- Inflow of the medium: The medium to be filtered is fed into the filter.

- Separation of the particles: The medium passes through the porous walls of the filter cartridges. Depending on the particle size, particles remain on the surface or in the depth structure of the filter cartridge.

- Clean outlet: The filtrate finally emerges clean from the filter unit.

Depending on the filter type and configuration, cartridge filters offer the option of cleaning the filter cartridges after soiling or regenerating them by backwashing in order to reuse them several times and thus extend the service life of the entire system. This not only reduces operating costs, but also protects the environment. In addition to the functions mentioned, FAUDI also offers cartridge filter systems that work with the special filtration process of precoat filtration.

Advantages of cartridge filters: clean medium, efficient processes

The use of a cartridge filter has numerous advantages, such as:

- High filtration accuracy: The precise function of the filter cartridges ensures thorough cleaning of the medium. The filter fineness of the available filter cartridges ranges from approx. 100 μm down to the range of approx. 0.1 μm.

- Long service life: Thanks to the high dirt-holding capacity of special filter cartridges and the regenerable filter cartridges, these systems are extremely economical.

- Flexibility: Our modular systems can be individually adapted to a wide range of applications and requirements.

- Environmentally friendly: The reusability of filter cartridges or parts of filter cartridges reduces waste and contributes to sustainable production.

Versatile use – areas of application for cartridge filters

Thanks to their flexibility and efficiency, cartridge filters can be used in numerous branches of industry. Depending on the design, they are suitable for both surface and depth filtration. They are used in the following industries:

- Automotive industry

- Chemicals and petrochemicals

- Water management

- Energy and environmental technology

- Rolling and steel industry

- Electroplating / surface treatment

- Metal processing industry

- Aviation industry

- Oil and gas industry

- Paint and varnish industry

- Food and beverage industry

Find the right cartridge filter type for your application

FAUDI stands for quality and innovation in industrial filtration – from the development to the implementation of customized solutions. We help you to find the right process and the right filter for your application.

Conclusion: The right choice for your filtration tasks

The functionality of cartridge filters is characterized by precision, flexibility and efficiency. Whether in the automotive industry, petrochemical industry, energy sector or food industry – our cartridge filters offer the right solution for every requirement. With high-quality materials and innovative technologies, Faudi ensures that your processes run smoothly and economically.