Precoat filtration: Efficient filtration solution for your application

Precoat filtration is one of the most advanced methods in industrial filtration and offers an efficient way of removing particles, suspended solids and other impurities from liquids. In this article, you will learn everything you need to know about how precoat filters work, their areas of application and the right filter solutions for your specific requirements. Discover how you can optimize your production processes with precoat filtration from Faudi.

What is precoat filtration?

Precoat filtration is a filtration technique in which a so-called filter aid is precoated onto a filter medium to form a filter cake. This filter cake takes over the filtration. This process enables precise separation of particles and liquids, even with very fine particles that would be difficult to capture with conventional filters.

The term “precoat filtration” is derived from the method in which the filter aid is “precoated” onto the filter medium. Precoat filters play an important role in many branches of industry, from the food and beverage industry to the chemical and pharmaceutical industries. This technology is particularly used when high filtration accuracy and efficiency are required.

How the precoat filter works

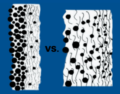

The FAUDI precoat filter consists of a pressure vessel and is divided into a dirty and clean side by an intermediate plate in which the filter elements are installed. The contaminated medium is filtered through the filter elements, whereby the flow through the filter elements is from the outside to the inside. However, before the actual filtration of the contaminated medium begins, the filter elements must be precoated with filter aids. During the so-called precoat process, the filter aid is deposited on the filter elements and forms a precoat layer, which ultimately determines the filtration fineness.

Depending on the filter aid used and the dirt content of the medium to be filtered, filter finenesses of between 3 and 10 µm can be achieved. After the precoating process, the actual filtration starts automatically. When the maximum filtration time is reached, the filter elements are completely cleaned by an automatic backwash and are available again for a new cycle.

The following steps are required for precoat filtration:

1. Precoating

The dissolved mixture of filter aid and clean medium is removed from the precoat tank with the filter pump and applied to the filter cartridge. The mixture flows through the filter cartridges from the outside to the inside. This precoating process is carried out until a sufficient layer of filter aid has built up on the cartridge.

2. Filtration

During filtration, the contaminated medium is removed from the dirt tank after the precoating process, applied to the filter elements and flowed through from the outside to the inside. During the filter cycle, the dirt particles accumulate on the precoat layer.

3. Regeneration

When the maximum differential pressure between the dirty and clean side of the filter is reached or a preset filtration time is reached, automatic regeneration or backwashing is triggered.

Areas of application for precoat filtration

The principle of precoat filtration is used in numerous industries that place high demands on the purity of their products.

Food and beverage industry

Precoat filtration is of great importance in the food and beverage industry, especially in the production of beverages such as beer, wine and juices. Here it is used to remove turbidity, yeast and other particles from the liquids in order to achieve a clear end product. Precoat filtration is also used in the production of sugar, edible oils and gelatine to ensure a high level of product purity.

Chemical and pharmaceutical industry

In the chemical and pharmaceutical industries, precoat filters are used to purify solvents, reagents and intermediate products. This industry places particularly high demands on filtration accuracy, as even the smallest impurities can impair the quality of the end products. Precoat filters offer a reliable solution for achieving the desired degree of purity.

Water treatment

Precoat filtration also plays an important role in water treatment. It is used to remove suspended solids, microorganisms and other undesirable substances from drinking water. This process is used in wastewater treatment in particular to reduce pollution and make the water usable again.

Metalworking and machine construction

In the metal and mechanical engineering industry, precoat filters are used to clean metal chips, abrasion and other impurities from cooling lubricants and other process fluids. This extends the service life of the machines, reduces maintenance costs and contributes to quality assurance.

The right filter solutions from Faudi

As a leading provider of filtration technology, Faudi offers you a range of precoat filters that impress with their high performance and reliability.

Faudi precoat filter

We offer customized precoat filters that have been specially developed for use in the above-mentioned industries. These filters are characterized by their robustness, long service life and easy handling. They are available in various designs to meet the specific requirements of your production process.

Filter aids and accessories

In addition to the actual filters, Faudi also offers a selection of high-quality filter aids and accessories that further increase the effectiveness of your precoat filtration. This includes a wide range of precoat aids such as diatomaceous earth, perlite and cellulose, which are optimally matched to the respective process requirements.

Customized solutions

We attach great importance to individual advice and customized solutions. Our experts work with you to develop a filtration concept that is optimally tailored to your needs. From selecting the right filter to integrating it into your production process – we support you with precoat filtration.

Would you like to use precoat filtration in your company?

Let our experts advise you! We are at your side and will work with you to develop the right filtration solution for your application. We look forward to your inquiry!

Conclusion: Optimize your filtration processes with precoat filtration

Precoat filtration offers numerous advantages for various industries and applications, especially when it comes to removing the finest particles and ensuring high product quality. With Faudi’s tailor-made precoat filters, you can optimize your filtration processes, increase efficiency and reduce operating costs at the same time.