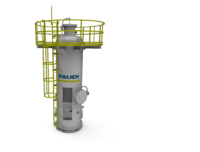

Bed filters: Activated charcoal filters (P62)

FAUDI activated charcoal filters are filled with a type of activated charcoal matched to the application. The number of applications of activated charcoal in industry is almost unlimited and cleaning processesusing activated charcoal is a process technology that has already proven itself over many years and remains technologically “state of the art”.

Activated charcoal is a natural product made, for example, from coal, wood, peat, olive stones and coconut shells. The porous charcoal in powder or granule form has a very large surface area. Therefrom results the useful effect of activated charcoal, which is based on the principle of adsorption.

Contaminants of almost all types of organic compounds as well as a vast majority of pesticides and solvents can be bound by activated charcoal and thus be removed. FAUDI activated charcoal filters are used for the treatment and purification of both liquids and gases. The purpose is to remove troublesome substances such as oils, hydrocarbons or undesirable smells and tastes, and in some cases toxic chemicals and heavy metals from liquids and gases.

We offer a flexible range of activated charcoal filters for numerous applications, such as filtration of amines (DEA, MDEA), water and wastewater treatment, gas purification, supply air purification, removal of heavy metal compounds from biogas (mercury, cadmium), removal of H2S (sulfur compounds) and dissolved organic pollutants from water (chlorine).

Benefits: Your advantages

at a glance

Versatile technology that has been

proven for many yearsConsistent filtrate quality

Low operating costs due to low differential pressure and long service life

Robust and functional design

Ready-to-use units or skids

Activated charcoal can be recycled by thermal reactivation

How does an activated charcoal

adsorber work?

Activated charcoal filters are activated charcoal adsorbers filled with special activated charcoal. The activated charcoal bed of these filters is operated in the down flow or up flow process. Best treatment qualities depend on the activated charcoal used and the filter design in terms of optimum contact time, flow rate and bed height.

As the contaminated medium slowly flows through the activated charcoal bed, the contaminants or dissolved substances are adsorbed on the large inner surface of the activated charcoal. As operation progresses, the loading of the activated carbon slowly increases.

In order to prolong the absorption capacity of the activated charcoal filter filling and the process quality, particulate residues can be separated by back flushing the activated charcoal bed or installing a pre-filter (e.g. candle filter).