Sieve filters: Sieve basket filters

(S11 and S21)

Sieve basket filters are used for coarse or pre-filtration of liquid, viscous and gaseous media. The filtration task includes the retention of contaminants from the piping system such as rust and scale or the pre-filtration of the media from contaminants from the production process. The design of the strainer basket filter and the filter basket is adapted to the area of application and the customer’s requirements in order to achieve an optimum result. Thus, sieve basket filters can be found as protective filters for a wide variety of applications, e.g. in water and wastewater plants, sewage treatment plants, power stations, refineries or also in building services engineering. They are also used to protect pipelines, pumps and nozzles and also for protection of flow meters, fittings, measuring units and much more. Finally, FAUDI basket filters can be used as single filters for fluids of all types (liquid, gaseous or pasty). Our sieve basket filters in a welded design are available as single or double filters with fittings, instrumentation and interconnecting pipes.

Benefits: YOUR ADVANTAGES

AT A GLANCE

Compact design

Connections at the same

height in the inline versionRobust and user friendly

For high differential

pressuresLow pressure loss

Cleanable filter materials

Can be used as

pressure or suction filtersHeat tracing is possible

Double-filter design is

possible

Design layout

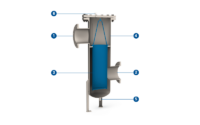

Sieve basket filters (S11)

The sieve basket filter consists of the following components:

1. Filter inlet

2. Filter outlet

3. Sieve basket

4. Filter housing

5. Drain

6. Vent

7. Separation plate

how does a

sieve basket

filter work?

The medium enters the sieve basket filter via the inlet connection and flows through the filter basket. The solid particles are retained by the filter fabric and the cleaned medium flows back into the pipe system via the outlet connection. The retained particles remain in the filter basket and, depending on their quantity and nature, will slowly impede the flow through the sieve basket filter. This leads to a measurable pressure difference before and after the filter basket and thus indicates the degree of contamination.